Metal Lined Slurry Pump

SPECIFICATIONS:

-Discharge diameters 1” to 18” (25mm to 450mm)

-Capacity: up to 5400 m3/h

-Head: up to 68m

-Speed: 200-3800r/min

-Materials: Cast iron, Ductile iron, High chrome alloy, Natural rubber etc

Kenda KH(R) Series Slurry Pumps | High Wear-resistant Industrial Transfer Solutions

KH series horizontal centrifugal slurry pumps and spare parts are fully interchangeable with the most common slurry pump designs in the industry. Metal and rubber lined pumps are of heavy-duty construction, designed for continuous pumping of highly abrasive and corrosive slurries. They feature a wide range of replaceable abrasion-resistant metal or molded elastomer casing liners and impellers, which are fully interchangeable within a common casting assembly.

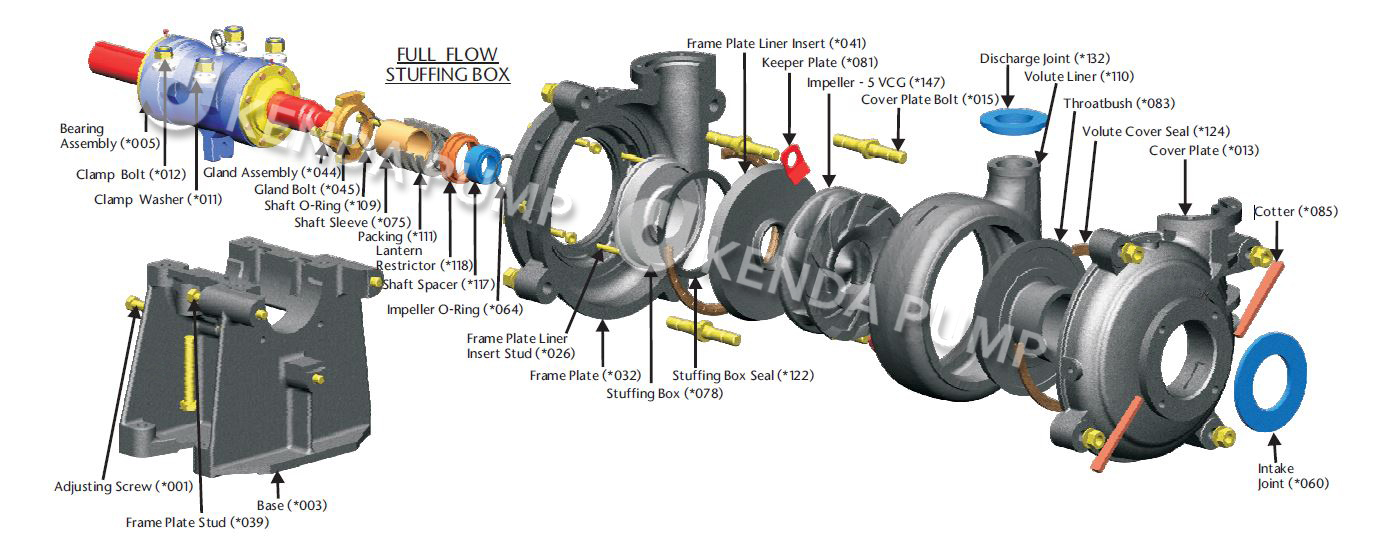

Kenda KH Slurry Pump Structure

Features

Pump- Cantilever, horizontal centrifugal slurry pump.

Wet parts-Impellers, volutes, liners are made of high chrome alloy or rubber or polyurethane, anti-abrasive, wear resistant and corrosion resistance.

Bearing assembly- Tubular structure bearing assembly, design of high capacity bearing. Grease lubrication, oil lubrication helps to adapt to different operating conditions.

Shaft seal- Sealed by packing or centrifugal.

Pump exit position- Based on 450 interval, rotating eight different angles of installation.

Kenda KH Series Slurry Pump Performance Chart

Model | Max. Motor Power (kW) | Material | Clear Water Performance | Impel. Dia. (mm) | |||||

Liner | Impeller | Capacity Q (m³/h) | Head H(m) | Pump Speed n(r/min) | Max. Eff. η% | NPSH (m) | |||

KH-1B | 15 | M | M | 12.6-28.8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

KHR-1B | 15 | RU | RU | 10.8-25.2 | 7-52 | 1400-3400 | 35 | 2-4 | 152 |

KHH-1C | 30 | M | M | 16.2-34.2 | 25-92 | 1400-2200 | 20 | 2-5.5 | 330 |

KH-1.5B | 15 | M | M | 32.4-72 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

KHR-1.5B | 15 | RU | RU | 25.2-54 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 |

KH-2C | 30 | M | M | 39.6-86.4 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

KHR-2C | 30 | RU | RU | 36-75.6 | 13-46 | 1300-2300 | 60 | 2-4 | 213 |

KHH-2D | 60 | M | M | 68.4-136.8 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

KH-3C | 30 | M | M | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

KH-3D | 60 | M | M | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

KHR-3C | 30 | RU | RU | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

KHR-3D | 60 | RU | RU | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

KHH-3E | 120 | M | M | 126-252 | 12-97 | 600-1400 | 50 | 2-5 | 508 |

KH-4D | 60 | M | M | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

KH-4E | 120 | M | M | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

KHR-4D | 60 | RU | RU | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

KHR-4E | 120 | RU | RU | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

KHH-4F | 260 | M | M | 324-720 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

KHH-6S | 560 | M | M | 468-1008 | 20-94 | 500-1000 | 65 | 4-12 | 711 |

KH-6E | 120 | M | M | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

KH-6R | 300 | M | M | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

KHR-6E | 120 | RU | RU | 32-720 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

KHR-6R | 300 | RU | RU | 32-720 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

KH-8ST | 560 | M | M | 612-1368 | 11-61 | 400-850 | 71 | 4-10 | 686 |

KHR-8ST | 560 | RU | RU | 540-1188 | 12-50 | 400-750 | 75 | 4-12 | 686 |

KM-8E | 120 | M | M | 540-1440 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

KM-8R | 300 | M | M | 540-1440 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

KH-10ST | 560 | M | M | 936-1980 | 7-68 | 330-800 | 82 | 6 | 762 |

KHR-10ST | 560 | RU | RU | 720-1620 | 7-45 | 300-650 | 80 | 2.5-7.5 | 762 |

KH-12ST | 560 | M | M | 1260-2772 | 13-63 | 300-600 | 77 | 3-10 | 965 |

KHR-12ST | 560 | RU | RU | 1152-2520 | 13-44 | 300-500 | 79 | 3-8 | 965 |

KH-14TU | 1200 | M | M | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

KH-16TU | 1200 | M | M | 2160-5054 | 8-66 | 200-500 | 80 | 4.5-9 | 1245 |

KH-18TU | 1200 | M | M | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 1370 |

Applications:

• Mining | • Mineral processing | • Coal prep | • Cyclone feeds |

• Tunnel | • Chemical slurries | • Tailings | • Mill grinding |

• Ash handing | • Paper and Pulp | • Waste sludge | • Coarse sand |

• Lime mud | • Phosphoric acid | • Dredging | • Construction |

• Alumina Industry | • Power Plant | • Potash Fertilizer Plant | • Other industries |

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425