Slurry Pump Impeller

Standard Material:

High Chrome Alloy A05 (HRC 58-62)

Natural Rubber (Shore A 55-65)

Polyurethane (Shore A 85-95)

Ceramic (HV 1200-1500)

Kenda KH Slurry Pump Impellers | 100% Interchangeable with Warman AH

The slurry pump impeller is one of the most critical slurry pump wear parts, designed to transfer kinetic energy to abrasive and corrosive slurry. As the core rotating component of a slurry pump, the impeller directly affects flow rate, head, efficiency, and wear resistance. High-quality slurry pump impellers are widely used in mining, mineral processing, tailings transportation, dredging, and wastewater treatment, Kenda’s slurry pump impellers are fully interchangeable with the impellers used in Warman AH/HH/LM series slurry pumps.

Slurry Pump Impeller Function

A well-designed slurry impeller ensures stable slurry flow while minimizing turbulence and wear. Different slurry pump impeller designs are optimized for handling high-density slurry, large solid particles, or corrosive media. Choosing the right impeller can significantly reduce downtime and maintenance costs.

Slurry Pump Impeller Types

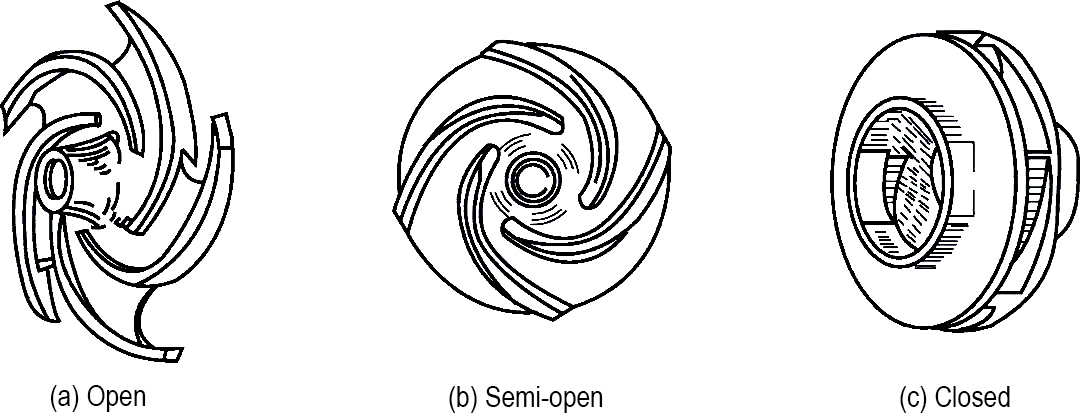

To meet different slurry conditions, slurry pump impellers are commonly available in the following types:

Open slurry pump impeller – suitable for large solid particles and non-clogging applications

Semi-open slurry pump impeller – ideal for medium solids concentration

Closed slurry pump impeller – provides higher efficiency for fine slurry with low solids

Slurry Pump Impeller Materials

Selecting the right slurry pump impeller material is essential to improve wear resistance and service life. Common materials include:

High chrome slurry pump impeller – excellent abrasion resistance for mining slurry

Rubber slurry pump impeller – ideal for corrosive slurry with fine particles

Polyurethane impeller – balanced wear and impact resistance

Stainless steel impeller – corrosion-resistant applications

Interchangeable Slurry Pump Impeller Code:

Impeller Code | Kenda KH Slurry Pump | AH Slurry Pump | Materials |

B1127 | KH1.5/1B | 1.5/1B-AH | High chrome, Natural rubber, Polyurethane |

B15127 | KH2/1.5B | 2/1.5B-AH | High chrome, Natural rubber, Polyurethane |

C2147 | KH3/2C | 3/2C-AH | High chrome, Natural rubber, Polyurethane |

C2127 | KH3/2C | 3/2C-AH | High chrome, Natural rubber, Polyurethane |

C2051 | KH3/2C | 3/2C-AH | High chrome, Natural rubber, Polyurethane |

D3147 | KH4/3C, 4/3D | 4/3C-AH, 4/3D-AH | High chrome, Natural rubber, Polyurethane |

D3145HE1 | KH4/3C, 4/3D | 4/3C-AH, 4/3D-AH | High chrome, Natural rubber, Polyurethane |

D3021 | KH4/3C, 4/3D | 4/3C-AH, 4/3D-AH | High chrome, Natural rubber, Polyurethane |

E4147 | KH6/4D, 6/4E | 6/4D-AH, 6/4E-AH | High chrome, Natural rubber, Polyurethane |

E4056 | KH6/4D, 6/4E | 6/4D-AH, 6/4E-AH | High chrome, Natural rubber, Polyurethane |

E4058 | KH6/4D, 6/4E | 6/4D-AH, 6/4E-AH | High chrome, Natural rubber, Polyurethane |

F6147 | KH8/6E, KH8/6F, KH8/6R | 8/6E-AH, 8/6F-AH, 8/6R-AH | High chrome, Natural rubber, Polyurethane |

F6056 | KH8/6E, KH8/6F, KH8/6R | 8/6E-AH, 8/6F-AH, 8/6R-AH | High chrome, Natural rubber, Polyurethane |

F6021 | KH8/6E, KH8/6F, KH8/6R | 8/6E-AH, 8/6F-AH, 8/6R-AH | High chrome, Natural rubber, Polyurethane |

F6058HE1 | KH8/6E, KH8/6F, KH8/6R | 8/6E-AH, 8/6F-AH, 8/6R-AH | High chrome, Natural rubber, Polyurethane |

FAM8147 | KH10/8F | 10/8F-AH | High chrome, Natural rubber, Polyurethane |

G8147 | KH10/8ST | 10/8ST-AH | High chrome, Natural rubber, Polyurethane |

FAM10147 | KH12/10F | 12/10F-AH | High chrome, Natural rubber, Polyurethane |

G10147 | KH12/10ST | 12/10ST-AH | High chrome, Natural rubber, Polyurethane |

FAM12147 | KH14/12F | 14/12F-AH | High chrome, Natural rubber, Polyurethane |

G12147 | KH14/12ST | 14/12ST-AH | High chrome, Natural rubber, Polyurethane |

GAM14147 | KH16/14TU | 16/14TU-AH | High chrome, Natural rubber, Polyurethane |

Impeller Code | Kenda KL Slurry Pump | L Slurry Pump | Materials |

175056 | KL20A | 20A-L | High chrome, Natural rubber |

32056 | KL50B | 50B-L | High chrome, Natural rubber |

43056 | KL75C | 75C-L | High chrome, Natural rubber |

64056 | KL100D | 100D-L | High chrome, Natural rubber |

86056 | KL150E | 150E-L | High chrome, Natural rubber |

108056 | KL200E | 200E-L | High chrome, Natural rubber |

SL30147 | KL300S | 300S-L | High chrome, Natural rubber |

SL35147 | KL350S | 350S-L | High chrome, Natural rubber |

STL40147 | KL400ST | 400ST-L | High chrome, Natural rubber |

STL45147 | KL450ST | 450ST-L | High chrome, Natural rubber |

TUL55147 | KL550TU | 550TU-L | High chrome, Natural rubber |

Impeller Code | Kenda KM Slurry Pump | M Slurry Pump | Materials |

F8147 | KM10/8E, KM10/8F, KM10/8R | 10/8E-M, 10/8F-M, 10/8R-M | High chrome, Natural rubber, Polyurethane |

F10147 | KM12/10F, KM12/10R | 12/10F-M, 12/10R-M | High chrome, Natural rubber, Polyurethane |

Impeller Code | Kenda KHH Slurry Pump | HH Slurry Pump | Materials |

CH1127 | KHH1.5/1C | 1.5/1C-HH | High chrome, Polyurethane |

DH2147 | KHH3/2D | 3/2D-HH | High chrome, Polyurethane |

EH3147 | KHH4/3E | 4/3E-HH | High chrome, Polyurethane |

FH4147 | KHH6/4F | 6/4F-HH | High chrome, Polyurethane |

FH6147 | KHH6S, KHH8/6S | 6S-H, 8/6S-H | High chrome, Polyurethane |

Impeller Code | Kenda KG(H) Gravel Pump | G(H) Gravel Pump | Materials |

DG4137 | KG6/4D,KG6/4E | 6/4D-G, 6/4E-G | High chrome |

EG6137 | KG8/6E | 8/6E-G | High chrome |

FG8137 | KG10/8F, KG10/8S | 10/8F-G, 10/8S-G | High chrome |

FG10137 | KG12/10G | 12/10G-G | High chrome |

GG12137 | KG14/12G | 14/12G-G | High chrome |

FGH8137 | KGH10/8F | 10/8F-GH | High chrome |

GGH10137 | KGH12/10G | 12/10G-GH | High chrome |

TG14148 | KGH16/14TU | 16/14TU-GH | High chrome |

Impeller Code | Kenda KP Vertical Slurry Pump | SP Vertical Slurry Pump | Materials |

SP4206 | KP40PV | 40PV-SP | High chrome, Natural rubber, Polyurethane |

SP65206 | KP65QV | 65QV-SP | High chrome, Natural rubber, Polyurethane |

SP10206 | KP100RV | 100RV-SP | High chrome, Natural rubber, Polyurethane |

SP15206 | KP150SV | 150SV-SP | High chrome, Natural rubber, Polyurethane |

SP20206 | KP200SV | 200SV-SP | High chrome, Natural rubber, Polyurethane |

SP25206 | KP250TV | 250TV-SP | High chrome, Natural rubber, Polyurethane |

SP30206 | KP300TV | 300TV-SP | High chrome, Natural rubber, Polyurethane |

Slurry Pump Main Parts Materials Standard:

Part Name | Part Code | Standard |

Bearing Assembly Frame Frame Plate & Cover Plate | HT200, HT250 | GB9439-88 |

QT450-10,QT500-7 | GB1348-88 | |

ZG230-450,ZG270-500 | GBT11352-89 | |

Impeller Volute Liner ThroatbushFrame Plate Liner Insert | High Chrome Alloy | GB8263-87 |

Ultra Chrome Alloy | GB8263-87 | |

Extra Chrome Alloy | GB8263-87 | |

Hyper Chrome Alloy | GB8263-87 | |

Expeller Expeller Ring | HT200, HT250 | GB9439-88 |

QT450-10, QT500-7 | GB1348-88 | |

Anti-corrosive Stainless Steel | GB2100-80 | |

High Chrome Alloy | GB8263087 | |

Shaft | 45# Steel | GB699-88 |

40CrMo | GB3077-88 | |

Shaft Sleeve | 45# Steel Coated Chrome | GB699-88 |

3Cr13 | GBT1220-92 |

FAQ:

1, Why Slurry Pump Impeller Wear Occurs?

-Slurry pump impeller wear mainly occurs due to abrasion from solid particles, corrosion from aggressive slurry, and improper impeller selection. Understanding why slurry pump impeller wear occurs helps users improve pump efficiency and extend impeller life.

2,How to Choose the Right Slurry Pump Impeller?

-When selecting a slurry pump impeller, consider slurry particle size, concentration, pH value, and operating speed. Choosing the best slurry pump impeller material and type can significantly improve performance and reduce operating costs.

Disclaimer: KENDA is not affiliated with or in any way connected to Warman® of Weir Minerals Group. All names, numbers, symbols, and descriptions are for reference only and do not suggest that any listed pumps or parts are products of Warman Pumps; Kenda slurry pump impellers are only compatible with Warman® slurry pump impellers. This document is the property of Kenda Pump and may not be reproduced or disclosed to any third party without prior written authorization.

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425