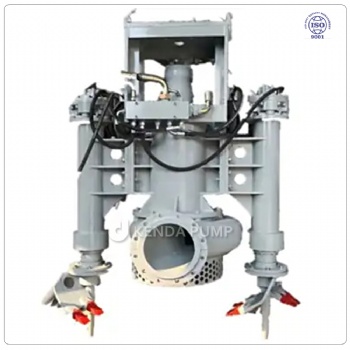

Explosion-proof Submersible Sewage Pump

SPECIFICATIONS:

-Capacity: 10-3000m3/h

-Head: 6-80m

-Speed: 1500-3000r/min

-Temperature Range: 0 - 40℃ (there are separate hot water pump models for temperatures exceeding this range).

-Materials: Cast iron, Cast steel, SS304, SS316L, High chrome alloy etc

Kenda KQ(B) Series Explosion-proof Submersible Pump

The KQ(B) series is an explosion-proof submersible pump for factory use. Its explosion-proof performance is manufactured as an explosion-proof type in accordance with the requirements of GB3836.1-2010 *Explosive Atmospheres - Part 1: Equipment - General Requirements* and GB3836.2-2010 *Explosive Atmospheres - Part 2: Equipment Protected by Flameproof Enclosures "d"*. Explosion-proof marking: ExdIIBT4/CT4. All pump products adopt a joint design and modeling, with a complete range of models, making selection convenient.

Main Application

The KQ(B) series products are used for sewage discharge in places where flammable gases or vapors form explosive mixtures with air, specifically in Zone 1 of factories, with IIB classification and temperature classes T1-T4. They are suitable for applications in coal chemical industry, petrochemical industry, municipal engineering, urban industry, hospitals, hotels, residential communities, and other similar places.

Operating conditions

1. Comply with and meet relevant explosion-proof requirements and safety specifications.

2. Power supply voltage: rated 380V, 660V, 1140V, three-phase, 50Hz.

3. Temperature of the conveyed medium: 0 - 40℃ (there are separate hot water pump models for temperatures exceeding this range).

4. pH value of the conveyed medium: 5 - 9.

5. Specific weight:≤11000N/m³

6. Maximum diving depth: 20m.

Kenda KQ(B) Series Explosion-proof Submersible Pump Structure

Features:

- Outstanding explosion-proof performance with clear explosion-proof markings - Anti-clogging design: Usually adopts structures such as large-flow-channel impellers and non-clogging designs, which can effectively pass solid particles of a certain particle size, prevent clogging, and ensure the continuous operation of the pump. - Suitable for underwater work: It can operate submerged in water, eliminating the need to build complex pump rooms, thus reducing project investment and floor space. - Equipped with reliable sealing structures, such as mechanical seals, to prevent water from entering the motor interior, ensuring the safe operation of the motor underwater and extending the service life of the equipment. - Small size and light weight: The overall structure is compact, occupying little space, and is convenient for transportation, installation and maintenance.

Kenda KQ(B) Series Explosion-proof Submersible Pump Performance Chart

No. | Model | Flow(m³/h) | Head(m) | Synchronous speed(r/min) | Power(kW) | Efficiency(%) | Outlet diameter(mm) |

1 | KQ(B) 18 - 6 - 1.5 | 18 | 6 | 3000 | 1.5 | 30 | 50 |

2 | KQ(B) 10 - 10 - 1.5 | 10 | 10 | 31 | |||

3 | KQ(B) 15 - 15 - 1.5 | 15 | 15 | 31 | |||

4 | KQ(B) 15 - 10 - 1.5 | 15 | 10 | 32 | |||

5 | KQ(B) 15 - 15 - 1.5 | 15 | 15 | 32.5 | |||

6 | KQ(B) 19 - 20 - 2.2 | 19 | 20 | 2.2 | 31 | ||

7 | KQ(B) 15 - 22 - 2.2 | 15 | 22 | 32.5 | |||

8 | KQ(B) 20 - 15 - 2.2 | 20 | 15 | 35 | |||

9 | KQ(B) 20 - 20 - 2.2 | 20 | 20 | 35 | |||

10 | KQ(B) 25 - 10 - 2.2 | 25 | 10 | 36 | |||

11 | KQ(B) 15 - 25 - 3 | 15 | 25 | 3 | 31.5 | ||

12 | KQ(B) 17 - 25 - 3 | 17 | 25 | 32 | |||

13 | KQ(B) 25 - 15 - 3 | 25 | 15 | 37 | |||

14 | KQ(B) 30 - 18 - 3 | 30 | 18 | 37.5 | |||

15 | KQ(B) 35 - 10 - 3 | 35 | 10 | 38 | |||

16 | KQ(B) 40 - 12 - 3 | 40 | 12 | 41.1 | 65 | ||

17 | KQ(B) 52 - 7 - 3 | 52 | 7 | 41.5 | 80 | ||

18 | KQ(B) 15 - 32 - 4 | 15 | 32 | 4 | 34.6 | 50 | |

19 | KQ(B) 20 - 22 - 4 | 20 | 22 | 41 | |||

20 | KQ(B) 28 - 20 - 4 | 28 | 20 | 41 | |||

21 | KQ(B) 25 - 22 - 4 | 25 | 22 | 37.8 | |||

22 | KQ(B) 25 - 28 - 4 | 25 | 28 | 37.8 | |||

23 | KQ(B) 30 - 20 - 4 | 30 | 20 | 38 | |||

24 | KQ(B) 50 - 50 - 8.5 | 50 | 50 | 43.3 | 80 | ||

25 | KQ(B) 12 - 50 - 5.5 | 12 | 50 | 5.5 | 33 | 50 | |

26 | KQ(B) 25 - 40 - 5.5 | 25 | 40 | 34 | |||

27 | KQ(B) 25 - 32 - 5.5 | 25 | 32 | 38 | |||

28 | KQ(B) 30 - 30 - 5.5 | 30 | 30 | 44 | |||

29 | KQ(B) 40 - 20 - 5.5 | 40 | 20 | 44.5 | |||

30 | KQ(B) 40 - 23 - 5.5 | 40 | 23 | 44.5 | |||

31 | KQ(B) 50 - 20 - 5.5 | 50 | 20 | 45 | |||

32 | KQ(B) 70 - 15 - 5.5 | 70 | 15 | 45.8 | 80 | ||

33 | KQ(B) 70 - 18 - 5.5 | 70 | 18 | 45.8 | |||

34 | KQ(B) 30 - 36 - 7.5 | 30 | 36 | 7.5 | 44.5 | 50 | |

35 | KQ(B) 30 - 40 - 7.5 | 30 | 40 | 44.5 | |||

36 | KQ(B) 40 - 35 - 7.5 | 40 | 35 | 45 | |||

37 | KQ(B) 50 - 30 - 7.5 | 50 | 30 | 55 | |||

38 | KQ(B) 75 - 20 - 7.5 | 75 | 20 | 55 | 80 | ||

39 | KQ(B) 100 - 12 - 7.5 | 100 | 12 | 55.3 | 100 | ||

40 | KQ(B) 25 - 48 - 11 | 25 | 48 | 1500 | 11 | 39 | 50 |

41 | KQ(B) 40 - 40 - 11 | 40 | 40 | 46 | 80 | ||

42 | KQ(B) 50 - 35 - 11 | 50 | 35 | 56 | |||

43 | KQ(B) 80 - 20 - 11 | 80 | 20 | 56.5 | 100 | ||

44 | KQ(B) 150 - 15 - 11 | 150 | 15 | 55.8 | 150 | ||

45 | KQ(B) 40 - 50 - 15 | 40 | 50 | 15 | 44 | 80 | |

46 | KQ(B) 50 - 40 - 15 | 50 | 40 | 45 | |||

47 | KQ(B) 60 - 35 - 15 | 60 | 35 | 45.3 | 100 | ||

48 | KQ(B) 100 - 22 - 15 | 100 | 22 | 48.6 | |||

49 | KQ(B) 170 - 18 - 15 | 170 | 18 | 56.5 | 150 | ||

50 | KQ(B) 200 - 15 - 15 | 200 | 15 | 57 | |||

51 | KQ(B) 50 - 50 - 18.5 | 50 | 50 | 18.5 | 45 | 80 | |

52 | KQ(B) 80 - 35 - 18.5 | 80 | 35 | 47 | 100 | ||

53 | KQ(B) 100 - 30 - 18.5 | 100 | 30 | 48 | |||

54 | KQ(B) 150 - 28 - 18.5 | 150 | 28 | 57.5 | 150 | ||

55 | KQ(B) 50 - 65 - 22 | 50 | 65 | 1500 | 22 | 45 | 80 |

56 | KQ(B) 60 - 50 - 22 | 60 | 50 | 45.8 | |||

57 | KQ(B) 80 - 40 - 22 | 80 | 40 | 47 | |||

58 | KQ(B) 100 - 40 - 22 | 100 | 40 | 52 | 100 | ||

59 | KQ(B) 150 - 30 - 22 | 150 | 30 | 59.3 | 150 | ||

60 | KQ(B) 200 - 20 - 22 | 200 | 20 | 60 | |||

61 | KQ(B) 80 - 60 - 30 | 80 | 60 | 30 | 48.5 | 80 | |

62 | KQ(B) 120 - 50 - 30 | 120 | 50 | 57.8 | 150 | ||

63 | KQ(B) 200 - 30 - 30 | 200 | 30 | 59 | |||

64 | KQ(B) 100 - 70 - 37 | 100 | 70 | 37 | 58.5 | 100 | |

65 | KQ(B) 150 - 45 - 37 | 150 | 45 | 62 | 150 | ||

66 | KQ(B) 150 - 50 - 37 | 150 | 50 | 62 | |||

67 | KQ(B) 150 - 50 - 45 | 150 | 50 | 45 | 57 | 150 | |

68 | KQ(B) 400 - 25 - 45 | 400 | 25 | 66 | 200 | ||

69 | KQ(B) 500 - 20 - 45 | 500 | 20 | 67 | 250 | ||

70 | KQ(B) 150 - 70 - 55 | 150 | 70 | 55 | 58 | 150 | |

71 | KQ(B) 200 - 50 - 55 | 200 | 50 | 59 | 200 | ||

72 | KQ(B) 400 - 30 - 55 | 400 | 30 | 66.6 | |||

73 | KQ(B) 200 - 70 - 75 | 200 | 70 | 75 | 58 | 150 | |

74 | KQ(B) 300 - 50 - 75 | 300 | 50 | 60.5 | 200 | ||

75 | KQ(B) 400 - 40 - 75 | 400 | 40 | 67 | |||

76 | KQ(B) 225 - 70 - 90 | 225 | 70 | 90 | 58.5 | 150 | |

77 | KQ(B) 300 - 60 - 90 | 300 | 60 | 62 | 200 | ||

78 | KQ(B) 400 - 60 - 110 | 400 | 60 | 100 | 69.8 | 250 | |

79 | KQ(B) 600 - 40 - 110 | 600 | 40 | 70 | 250 | ||

80 | KQ(B) 600 - 50 - 132 | 600 | 50 | 110 | 70 | 200 | |

81 | KQ(B) 500 - 60 - 132 | 500 | 60 | 69 | |||

82 | KQ(B) 700 - 50 - 160 | 700 | 50 | 160 | 71.3 | 250 | |

83 | KQ(B) 1000 - 35 - 160 | 1000 | 35 | 75 | 350 | ||

84 | KQ(B) 800 - 50 - 185 | 800 | 50 | 185 | 72.3 | 350 | |

85 | KQ(B) 1000 - 40 - 185 | 1000 | 40 | 73.8 | 300 | ||

86 | KQ(B) 1200 - 40 - 200 | 1200 | 40 | 200 | 76 | 350 | |

87 | KQ(B) 1500 - 32 - 200 | 1500 | 32 | 77.4 | 400 |

Applications:

• Petrochemical industry | • Municipal engineering | • Urban industry | |

• Hydraulic engineering | • Sewage | • Waste Water | • Effluent |

• Fibres | • Chemical waster water | • Sludge | • Civil air defence |

• Drainage | • Sewerage system | • Floodwater | • Mining waste |

• Pharmaceuticals | • Oil-field waste water | • Fodder liquids | • Construction |

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425