KM Centrifugal Sand Pump

SPECIFICATIONS:

Sizes from 3x2x13 to 10x8x14

Flow rates up to 2,600 GPM

Head pressure up to 550 feet

Best utilized for applications requiring up to 200 HP

KM Series Centrifugal Sand Pump | Pumps for Solids Control Systems

KM series centrifugal sand pump mainly supplies to solids control circulating system of oilfield drill rig,and be used to provide drilling liquid with a certain discharge capacity and pressure to desander, desilter and mud mixer, to assure these equipments work efficiently.

The KM10×8×14 centrifugal sand pump applies to over 3000-meter-long drilling rigs,with big viscosity and specific gravity drilling fluid.

The KM 8×6×14 centrifugal sand pmp applies to over 3000-meter-long drilling rigs.

The KM 8×6×11 centrifugal sand pump applies to under 3000-meter-long drilling rigs,also can be can be used to supply mud to triplex mud pump as a filling pump.

The KM 6×5×11 centrifugal sand pump applies to truck-mounted drilling rigs or pocket drilling rigs.

The KM 4×3 centrifugal sand pump is usually used as measuring pump or replenishment pump.

The KM 3×2 centrifugal sand pump is usually used as clean water pump.

Features

• Up to 50% more capacity from the 8 x 6 pump

• Optimum pressure at low operating speeds

• Thicker casing to extend life from wear and corrosion

• New impeller design to reduce loads and extend bearing life

• Larger, stronger shaft to reduce deflection

• Replaceable shaft sleeve in packing wear area

• Larger, long-life bearings

• Replaceable stuffing box cover

• Smoother, non-turbulent flow throughout casing

Typical Configurations:

3x2x13 6x5x14

4x3x13 8x6x11

5x4x14 8x6x14

6x5x11 10x8x14

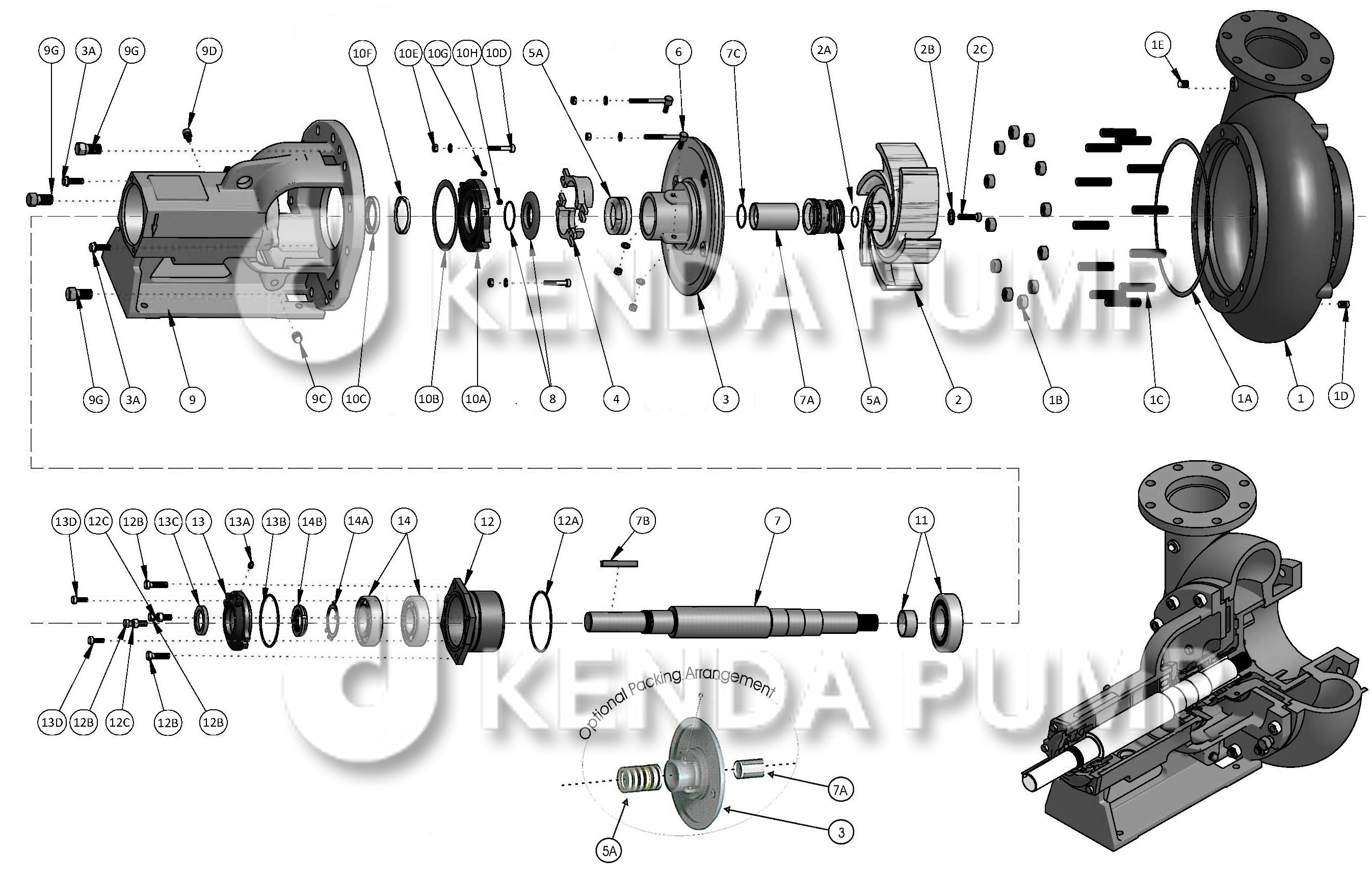

Kenda KM Series Centrifugal Sand Pump Parts List

![]()

Item | Qty | OEM Part No. | Description | Material | Weight (kg) | ||

1* | 1 | See below | Casing | ||||

1A | 1 | 10399-46-1 | Gasket,casing | Vellumoid | 0.01 | ||

1B | 12 | 3932-61 | Nut,casing | Stl | 0.05 | ||

1C | 12 | 3862-76 | Stud,casing | Stl | 0.16 | ||

1D | 1 | 8505-04-01 | Plug,Casing Drain | Stl | 0.03 | ||

1E | 1 | 8505-04-01 | Plug,flush line | Stl | 0.03 | ||

2* | 1 | See below | Impeller | ||||

2A | 1 | 19110-72 | Seal,impeller | Viton | 0.002 | ||

2B | 1 | 7300239 | Washer,impeller | Stl | 0.02 | ||

2C | 1 | 7415648 | Bolt,impeler lock | Stl | 0.15 | ||

3*# | 1 | 22223-01-30 | Stuffing box,mech.seal | Hard Iron | 20 | ||

3*& | 1 | 20614-01-30 | Stuffing box,packed | Hard Iron | 20 | ||

3A | 2 | 3861-117 | Bolt,stuffing box | Stl | 0.05 | ||

4 | 1 | 20622A | Gland assy,packing | Stl 304 | 1 | ||

5A# | 1 | 22451-1 | Seal,mechanical | Tung/Tung | 1 | ||

5A# | 1 | 648402600 | Packing, Shaft - M.S. Backup | Graphite Acrylic | 0.3 | ||

5A# | Option | 648402600 | Packing, Shaft - M.S. Backup | Kevlar | 0.3 | ||

5A | 1 | 25014-04M-B | Packing, Shaft - w/latern ring | Graphite/Acrylic | 0.5 | ||

5A | Option | 250147-04M-D | Packing, Shaft - w/latern ring | Teflon, White | 0.5 | ||

5A# | Option | 25014-04M-C | Packing, Shaft - w/latern ring | Kevlar | 0.5 | ||

6 | 2 | B3701A | Bolt assy,gland | Stl 304 | 0.15 | ||

7 | 1 | 20612-02-33 | Shaft | 42CrMo | 17 | ||

7A | 1 | 20943-04A | Sleeve,shaft | 38CrMoAl | 1 | ||

7B | 1 | 4371-5-21 | Key,shaft | Stl | 0.11 | ||

7C | 1 | 23444-01-72 | Seal,shaft sleeve | Viton | 0.005 | ||

8 | 1 | 22210-1A | Deflector assembly | Composite | 0.4 | ||

9 | 1 | 20618-12-1 | Frame,grease lubricated | Cast iron | 80 | ||

9C | 1 | 8505-04-01 | Plug, Frame Drain | Stl | 0.033 | ||

9D | 1 | 8267-01 | Breather | Stl | 0.1 | ||

9G | 3 | 2538-1H | Bolt,casing jack | Stl | 0.16 | ||

10A | 1 | 20626 | Cover,inboard bearing | Iron | 2.6 | ||

10B | 1 | 20625 | Gasket,I.B.Brg.Cover | Vegetable fiber | 0.01 | ||

10C | 1 | 20619-01 | Oil seal, I.B.Brg.Cover | Buna-n | 0.06 | ||

10D | 2 | 3861-1 | Bolt, I.B.Brg.Cover | Stl | 0.03 | ||

10E | 2 | 3932-2 | Nut, I.B.Brg.Cover | Stl | 0.07 | ||

10F | 1 | 20620-01 | Exclusion Seal, I.B. Brg. Cvr. | Buna-n | 0.01 | ||

10G | 1 | 21641-01 | Grease fitting | Stl | 0.07 | ||

10H | 1 | 648411908 | Grease fitting | Stl | 0.07 | ||

11 | 1 | 661 00901 OA | Bearing, Inboard & Spacer | Roller | 2.1 | ||

11 | 1 | 20615-1 | Bearing,inboard | Vendor | 2.1 | ||

12 | 1 | 20624-01-01 | Housing,O.B.bearing | Iron | 6 | ||

12A | 1 | 7496-253 | Seal, O.B.Brg.housing | Buna-n | 0.01 | ||

12B | 4 | 3861-138 | Bolts, O.B.Brg.housing | Stl | 0.05 | ||

12C | 2 | 3932-62 | Nut, O.B.Brg.housing jam | Stl | 0.016 | ||

13 | 1 | 20617A | Cover,O.B.Bearing | Iron | 1.8 | ||

13A | 1 | 19368-01 | Grease zerk, O.B.Brg.Cover | Brass | 0.01 | ||

13B | 1 | 7496-26 | O-ring, O.B.Brg.Cover | Buna-n | 0.001 | ||

13C | 1 | 20619-02 | Oil seal, O.B.Brg.Cover | Buna-n | 0.04 | ||

13D | 2 | 3861-139 | Bolt, O.B.Brg.Cover | Stl | 0.025 | ||

14 | 2 | 20616-1 | Bearing, O.B. | Vendor | 1.5 | ||

14A | 1 | 6124-4 | Lockwasher,O.B.Bearing | Stl | 0.01 | ||

14B | 1 | 6123-4 | Locknut, O.B.Bearing | Stl | 0.22 | ||

Casings-includes studs,nuts & gasket | |||||||

1* | 1 | 19203-01-30A | Casing,3×2×13 | Hard Iron | 55 | ||

1* | 1 | 19205-01-30A | Casing,4×3×13 | Hard Iron | 57 | ||

1* | 1 | 19222-01-30A | Casing, 5×4×14 | Hard Iron | 88 | ||

1* | 1 | 19122-01-30A | Casing,6×5×11 | Hard Iron | 90 | ||

1* | 1 | 19123-01-30A | Casing, 6×5×14 | Hard Iron | 95 | ||

1* | 1 | 19763-01-30A | Casing, 8×6×11 | Hard Iron | 97 | ||

1* | 1 | 19117-01-30A | Casing,8×6×14 | Hard Iron | 125 | ||

1* | 1 | 20937-01-30A | Casing,10×8×14 | Hard Iron | 155 | ||

Impellers | |||||||

2* | 1 | 19204-XX-30 | Impeller,3×2×13 | Hard Iron | 9 | ||

2* | 1 | 19206-XX-30 | Impeller,4×3×13 | Hard Iron | 12.5 | ||

2* | 1 | 19224-XX-30 | Impeller,5×4×14 | Hard Iron | 16 | ||

2* | 1 | 19121-XX-30 | Impeller,6×5×11 | Hard Iron | 14 | ||

2* | 1 | 19121-XX-30 | Impeller, 6×5×14 | Hard Iron | 18 | ||

2* | 1 | 19121-XX-30 | Impeller, 8×6×11 | Hard Iron | 18 | ||

2* | 1 | 19116-A0-30 | Impeller,8×6×14 | Hard Iron | 20 | ||

2* | 1 | 21867-XX-30 | Impeller,10×8×14 | Hard Iron | 20 | ||

Note:1. XX-Impeller code-Firsr X equals diameter of impeller in inches minus 4.Therefore 10″=6,9″=5 etc…14″ use lettet A;

2. Second X equals frational data in1/8′s.Therefore 1/8″=1, 1/4″=2 ,etc…Thus a 10.5″impeller is coded as 64, 12″impeller is coded as 80, 13.25″impeller is coded as 92 etc…

3. YYY-the metric diameter of impeller,therefore 12″ is coede as 305mm,11″ is coded as 280mm

Application:

• Barite, ferric oxide, and mineral oil | • Base drilling muds | • Glass fibers | • Sugar processing |

• coal conveyers | • Cement | • Mine de-watering | • Lime slurries |

• Kaolin clay | • Crystalline forms | • Ash handling | • Mineral Processing |

Disclaimer:

Kenda Pump is a Chinese company. It neither represents Mission Magnum® of NOV Group nor has any affiliation with the brand. All names, numbers, symbols, and descriptions contained herein are for reference only and do not imply that any pumps or parts listed are products of Mission Magnum Pumps.

Kenda sand pumps and spares are only interchangeable with those of Mission Magnum.

This document is the exclusive property of Kenda Pump. It may not be reproduced or disclosed to any third party without written authorization.

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425