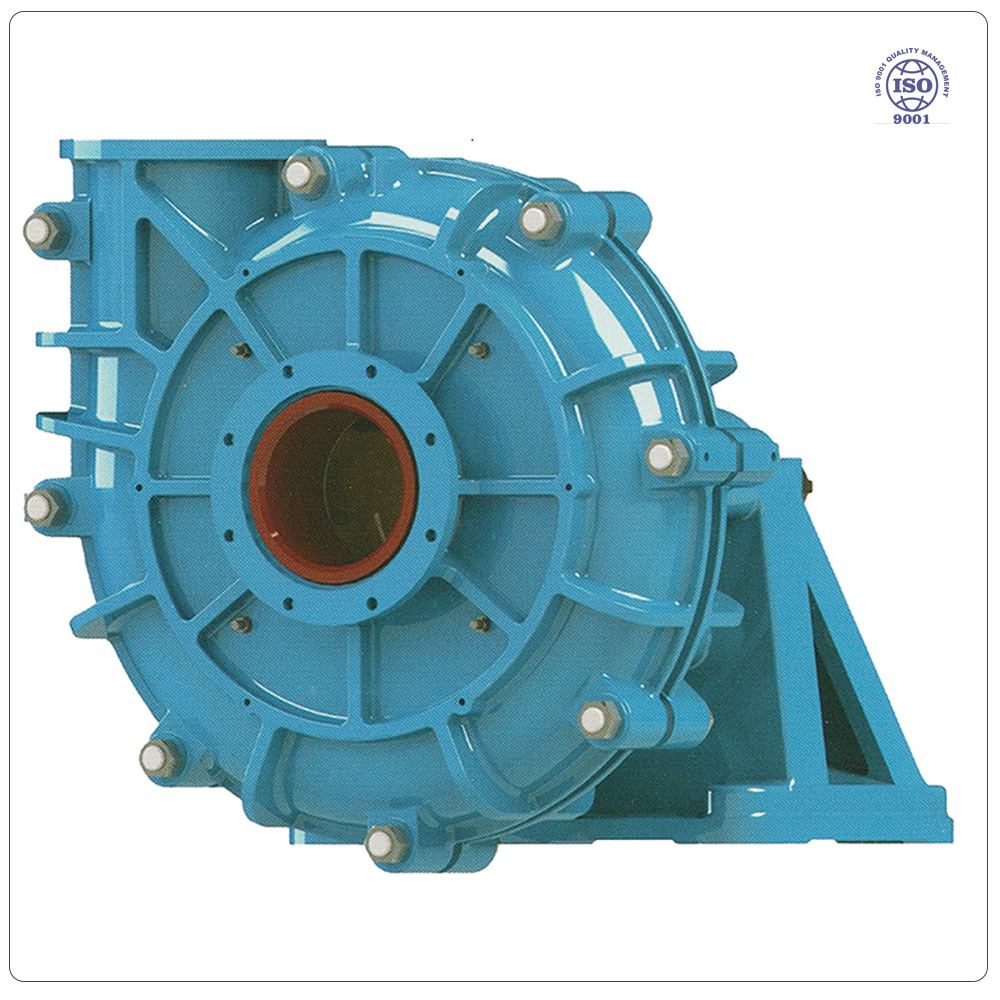

Silicon Carbide Slurry Pump

SPECIFICATIONS:

-Discharge diameters 1” to 18” (25mm to 450mm)

-Capacity: up to 6000 m3/h

-Head: up to 110m

-Speed: 490-2900r/min

-Material: Silicon Carbide

Kenda KHT Series Silicon Carbide Slurry Pump

KHT series pump features an external metal structure to withstand high pressure and a silicon carbide lining. Silicon carbide offers wear resistance, corrosion resistance and high-temperature resistance, making it suitable for industries like mining, metallurgy, electric power, coal and chemical engineering to transport slurries containing solid particles and corrosive substances.

As a technically mature wear - resistant material, silicon carbide (SiC) has high hardness, stable molecular structure, and excellent wear - corrosion resistance, corrosion resistance, and high - temperature resistance. It has been widely used in industries such as mining, metallurgy, electric power, and chemical engineering. In the field of slurry pumps at home and abroad, the working conditions are mostly dominated by strongly corrosive and strongly abrasive media, and the service environment is harsh. This requires that the materials of the flow - passing parts have good corrosion resistance and wear - corrosion resistance. Silicon carbide ceramics (including silicon carbide sintered ceramics bonded with silicon nitride and silicon carbide composite ceramics bonded with resin) are an excellent choice.

Strong Corrosion Resistance of Silicon Carbide

- Good chemical stability, resistant to the corrosion of almost all inorganic acids, organic acids and alkalis, and has excellent oxidation resistance.

- Extremely strong wear resistance, 3 - 5 times that of high - chromium wear - resistant steel;

- Excellent corrosion resistance - resistant to various acids, alkalis and chemicals except hydrofluoric acid and hot concentrated alkalis;

- Good impact resistance, can resist the impact of large particles and steel balls;

- Wide temperature range, can be used for a long time from - 40℃ to 90℃, and the maximum service temperature can reach 110℃.

Strong Wear Resistance of Silicon Carbide

The crystal structure of silicon carbide is similar to the regular tetrahedral structure of diamond. It is a compound mainly combined by covalent bonds, and its hardness is second only to that of diamond, its wear resistance is 3.51 times that of G30 wear - resistant steel.

KHT Series Silicon Carbide Slurry Pump Structure

KHT Series Silicon Carbide Slurry Pump Performance Table

Model | Flow(m³/h) | Head(m) | Speed(r/min) | Shaft Power(kw) | Motor Power(kw) | Efficiency (%) | NPSH (m) | Impeller(mm) | Weight(kg) |

450KHT - 950 | 2916 | 51 | 590 | 506.25 | 800 | 80 | 4 | 950 | 12000 |

4680 | 43 | 644.75 | 85 | 10 | |||||

6048 | 38 | 782.35 | 80 | 10 | |||||

450KHT- 950 | 2368 | 35 | 490 | 270.22 | 450 | 80 | 3 | 950 | |

3960 | 30 | 380.62 | 85 | 6 | |||||

4824 | 25 | 410.54 | 80 | 9 | |||||

400KHT - 850 | 2520 | 52 | 740 | 446.08 | 630 | 80 | 4 | 850 | 8000 |

3960 | 45 | 557.81 | 87 | 8 | |||||

5040 | 35 | 600.49 | 80 | 10 | |||||

400KHT - 850 | 2160 | 38 | 590 | 279.41 | 450 | 80 | 4 | 850 | |

3528 | 33 | 364.44 | 87 | 8 | |||||

4320 | 26 | 382.35 | 80 | 9 | |||||

350KHT - 1067 | 1440 | 65 | 550 | 364.15 | 800 | 70 | 4 | 1067 | 14000 |

2700 | 60 | 551.47 | 80 | 7 | |||||

3600 | 55 | 657.58 | 82 | 10 | |||||

350KHT - 1067 | 1510 | 51 | 490 | 299.60 | 630 | 70 | 4 | 1067 | |

2370 | 49 | 395.32 | 80 | 6 | |||||

3600 | 42 | 508.35 | 81 | 10 | |||||

350KHT - 750 | 1224 | 48 | 740 | 228.57 | 400 | 70 | 4 | 750 | 6500 |

1944 | 44 | 291.18 | 80 | 5 | |||||

2488 | 40 | 332.54 | 81.5 | 8 | |||||

350KHT - 750 | 936 | 31 | 590 | 112.89 | 200 | 70 | 3 | 750 | |

1512 | 28 | 144.12 | 80 | 4 | |||||

2160 | 23 | 169.12 | 80 | 7 | |||||

300KHT - 1027 | 943 | 61 | 590 | 261.09 | 500 | 60 | 4.9 | 1027 | 6400 |

1692 | 58 | 361.16 | 74 | 8 | |||||

2455 | 52 | 451.50 | 77 | 13 | |||||

300KHT - 1027 | 792 | 43 | 490 | 154.58 | 315 | 60 | 4 | 1027 | |

1440 | 41 | 217.28 | 74 | 6 | |||||

2088 | 36 | 265.85 | 77 | 10 | |||||

300KHT - 660 | 1260 | 60 | 940 | 294.12 | 450 | 70 | 6 | 660 | 2800 |

1872 | 54 | 352.94 | 78 | 10 | |||||

2700 | 43 | 405.35 | 78 | 12 | |||||

300KHT - 660 | 972 | 38 | 750 | 143.70 | 250 | 70 | 3 | 660 | |

1476 | 34 | 175.21 | 78 | 6 | |||||

2160 | 28 | 211.16 | 78 | 10 | |||||

250KHT - 813 | 943 | 61 | 590 | 261.09 | 500 | 60 | 4.9 | 813 | 4318 |

1692 | 58 | 361.16 | 74 | 8 | |||||

2455 | 52 | 451.50 | 77 | 13 | |||||

250KHT - 813 | 792 | 43 | 490 | 154.58 | 315 | 60 | 4 | 813 | |

1440 | 41 | 217.28 | 74 | 6 | |||||

2088 | 36 | 265.85 | 77 | 10 | |||||

200KHT - 740 | 720 | 85 | 980 | 277.78 | 450 | 60 | 6 | 737 | 3750 |

1080 | 80 | 326.80 | 72 | 9 | |||||

1440 | 75 | 392.16 | 75 | 11 | |||||

200KHT - 740 | 540 | 50 | 730 | 122.55 | 250 | 60 | 4 | 737 | |

1080 | 45 | 183.82 | 72 | 6 | |||||

1440 | 40 | 224.09 | 70 | 8 | |||||

200KHT - 580 | 576 | 50 | 980 | 130.72 | 250 | 60 | 4 | 580 | 2350 |

972 | 45 | 163.17 | 73 | 8 | |||||

1404 | 38 | 207.56 | 70 | 14 | |||||

200KHT - 580 | 468 | 28 | 740 | 59.48 | 110 | 60 | 3 | 580 | |

756 | 26 | 75.39 | 71 | 6 | |||||

1152 | 20 | 89.64 | 70 | 10 | |||||

150KHT - 712 | 300 | 95 | 980 | 155.23 | 185 | 50 | 4.2 | 712 | 6586 |

540 | 92 | 225.49 | 250 | 60 | |||||

720 | 90 | 271.49 | 315 | 65 | |||||

150KHT - 712 | 300 | 55 | 740 | 89.87 | 110 | 50 | 4.2 | 712 | |

540 | 50 | 122.55 | 160 | 60 | |||||

720 | 45 | 135.75 | 185 | 65 | |||||

150KHT - 560 | 270 | 62 | 1200 | 91 | 200 | 50 | 4.9 | 560 | 1655 |

450 | 60 | 113 | 65 | 5 | |||||

594 | 57 | 131 | 70 | 6 | |||||

150KHT - 560 | 229 | 46 | 980 | 57 | 110 | 50 | 4 | 560 | |

432 | 44 | 78 | 66 | 6 | |||||

635 | 38 | 93 | 72 | 6.5 | |||||

100KHT - 711 | 180 | 100 | 980 | 122.55 | 160 | 40 | 3.5 | 711 | 2880 |

360 | 95 | 169.34 | 185 | 55 | |||||

540 | 90 | 209.42 | 250 | 63.2 | |||||

100KHT - 711 | 180 | 55 | 740 | 67.40 | 75 | 40 | 3.5 | 711 | |

360 | 50 | 89.13 | 110 | 55 | |||||

540 | 45 | 104.71 | 132 | 63.2 | |||||

100KHT - 400 | 129 | 54 | 1480 | 38 | 90 | 65 | 4 | 400 | 728 |

248 | 49 | 51 | 50 | 5 | |||||

356 | 43 | 61 | 68 | 7 | |||||

100KHT - 400 | 86 | 23 | 980 | 11 | 37 | 50 | 4 | 400 | |

162 | 21 | 14 | 65 | 6 | |||||

234 | 18 | 17 | 68 | 6.5 | |||||

80HT - 510 | 107 | 110 | 1480 | 53.78 | 75 | 59.6 | 3.5 | 510 | 1250 |

182 | 105 | 80.07 | 110 | 65 | |||||

242 | 99 | 97.82 | 132 | 66.7 | |||||

80HT - 510 | 107 | 45 | 980 | 22.00 | 30 | 59.6 | 3.5 | 510 | |

182 | 42 | 32.03 | 37 | 65 | |||||

242 | 38 | 37.55 | 45 | 66.7 | |||||

80KHT - 265 | 50 | 28 | 1480 | 7.63 | 30 | 50 | 2 | 265 | 363 |

94 | 26 | 10.08 | 66 | 3 | |||||

137 | 23 | 12.26 | 70 | 4 | |||||

80KHT - 265 | 28 | 11 | 980 | 1.68 | 7.5 | 50 | 2.2 | 265 | |

68 | 10 | 2.68 | 69 | 2.2 | |||||

108 | 16 | 7.24 | 65 | 2.2 | |||||

50HT - 460 | 57 | 85 | 1480 | 41.23 | 55 | 32 | 3 | 460 | 750 |

91 | 82 | 48.38 | 75 | 42 | |||||

111 | 80 | 53.74 | 75 | 45 | |||||

50HT - 460 | 57 | 42 | 980 | 20.37 | 30 | 32 | 3 | 460 | |

91 | 40 | 23.60 | 37 | 42 | |||||

111 | 35 | 23.51 | 37 | 45 | |||||

50KHT - 230 | 46.8 | 62 | 2900 | 17.56 | 30 | 45 | 4 | 230 | 276 |

79.2 | 58 | 22.75 | 55 | 7 | |||||

115.2 | 50 | 27.52 | 57 | 12 | |||||

50KHT - 230 | 18 | 22 | 1480 | 3.59 | 15 | 30 | 2 | 230 | |

50.4 | 20 | 4.9 | 56 | 3 | |||||

79.2 | 26 | 10.20 | 55 | 6 |

Application

• Mining | • Mineral processing | • Cyclone feed pump | • Chemical Industry |

• Ash handing | • Paper and Pulp | • Waste sludge | • Coarse sand |

• Lime mud | • Phosphoric acid | • Ore dressing | • Tailings conveyor |

•Environmental Protection | • Coal-fired Power | • Iron and Steel | • Smelting |

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425