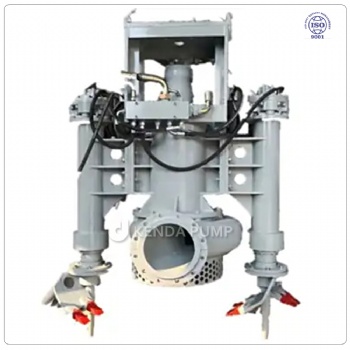

Submersible Drainage Pump

SPECIFICATIONS:

-Capacity: up to 160 m3/h

-Head: up to 57 meters

-Power: 1.5kW(2HP) to 15 kW (20HP)

-Power supply: three phase 380V ± 10%, 50Hz/ 60Hz

-Water temperature: up to 40℃

-Max. water depth: 25 m

-Materials: Cast iron, Ductile Iron, High chrome alloy etc

Kenda KZ Series Submersible Pump Characteristics

The body of motor and pump is made of rigid cast iron for long-lasting durability.

Greatly increased maximum submersion depth due to mechanical seal resistant to high pressure.

Semi-open impeller made of high chrome alloy matching with wear plate (ductile iron) achieves superior durability.

Effective motor cooling due to discharge channel cast as part of the motor housing. Top outlet design saves space required for installation.

Discharge 50mm(2'') to 150mm(6''), motor 1.5kW (2HP) to 15 kW (20HP).

Application

Civil engineering

Mines, quarries, coal ore & slurries

Sewage treatment plants

General pumping purposes

Specification

Capacity: up to 160m³/h

Head: up to 57 meters

Power: 1.5kW (2HP) to 15 kW (20HP)

Power supply: three phase 400V ±10%, 50Hz / 60Hz

Insulation class: F

Protection class: IP68

Cable length: 8m

Water temperature: up to 40℃

Max. water depth: 25m

Kenda KZ Series Submersible Pump Structure and Dimension

Applications:

• Coal chemical industry | • Petrochemical industry | • Municipal engineering | • Urban industry |

• Hydraulic engineering | • Sewage | • Waste Water | • Effluent |

• Fibres | • Chemical waster water | • Sludge | • Civil air defence |

• Drainage | • Sewerage system | • Floodwater | • Mining waste |

• Pharmaceuticals | • Oil-field waste water | • Fodder liquids | • Construction |

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425