Sand Gravel Pump

Specifications

-Discharge diameters 4” to 14” (100mm to 350mm)

-Flow rates to 3000m3/h

-Heads to 70m

-Speed: 250-1400rpm

-Material: Ductile iron, High chrome alloy A05 etc.

Kenda KG(H) Series Sand Gravel Pump

KG(H) pump are designed for continuously handling the most difficult higher abrasive, large particle slurries which other series pump cannot handle, large passage inside casing make it the best choice for gravel, dredging and other applications where large particles needed to be handled, especially for big flow, high concentration, high head media.

Specifications

Discharge diameters 4” to 14” (100mm to 350mm)

Heads to 70m

Flow rates to 3000m3/h

Features

Pump- Single pump casing, horizontal gravel sand pump.

Wet parts-Impellers, volutes are made of high chrome alloy, anti-abrasive, wear resistant.

Bearing assembly- cylindrical bearing assembly, easy to adjust the gap between impeller and pump body, which can be removed as a whole at the time of maintenance.

Shaft seal type- expeller seal, packing seal, mechanical seal.

Drive arrangements- V-type triangular belt drive, flexible coupling drive, gear reducer drive, fluid coupling drive, thyristor speed control, etc.

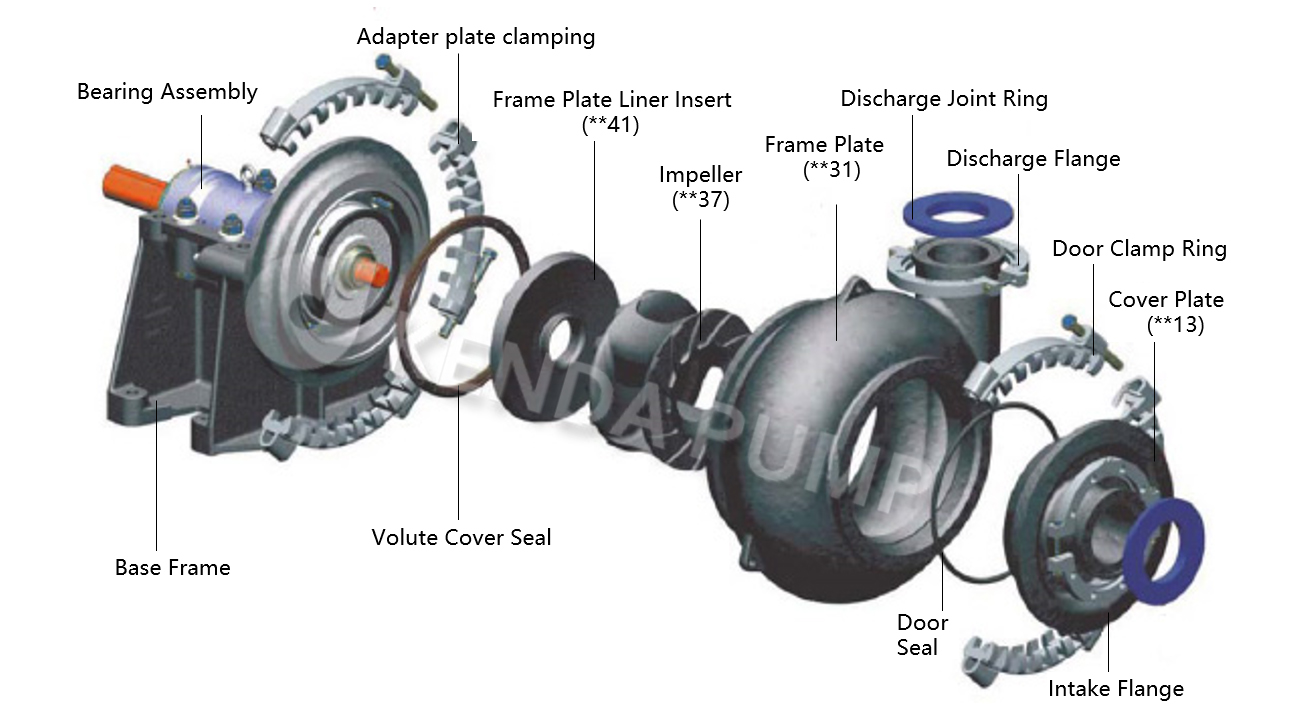

Kenda KG(H) Series Sand Gravel Pump Structure

Kenda KG(H) Series Sand Gravel Pump Performance Chart

Model | Outlet Diameter (mm) | Pump Speed n(r/min) | Capacity (m³/hr) | Head H(m) | Max. Eff. η% | Max. Motor Power Kw | Impel. Dia. (mm) | Allowable Max. Particle Size |

KG-4D | 100 | 600-1400 | 36-250 | 7-56 | 50 | 60 | 378 | 82 |

KG-6E | 150 | 800-1400 | 180-540 | 12-52 | 60 | 120 | 378 | 120 |

KG-8F | 200 | 500-1000 | 180-820 | 12-56 | 60 | 260 | 533 | 178 |

KG-8S | 200 | 500-1000 | 180-820 | 12-56 | 60 | 560 | 533 | 178 |

KG-10G | 250 | 400-850 | 360-1200 | 12-60 | 65 | 600 | 667 | 220 |

KG-12G | 300 | 300-700 | 700-2700 | 8-70 | 65 | 600 | 864 | 241 |

KG-12TU | 300 | 300-700 | 700-2700 | 8-70 | 65 | 1200 | 864 | 241 |

KGH-6F | 150 | 500-1000 | 180-900 | 20-90 | 60 | 260 | 610 | 140 |

KGH-8S | 200 | 500-1100 | 50-900 | 20-78 | 70 | 560 | 610 | 180 |

KGH-10G | 250 | 350-700 | 500-2000 | 20-78 | 70 | 600 | 915 | 210 |

KGH-14TU | 350 | 250-500 | 1000-2800 | 20-70 | 70 | 1200 | 1220 | 230 |

Application

--Dredger operations: Suitable for dredging, efficiently transporting mud containing large amounts of sediment, gravel and other particles, meeting the material conveying needs of dredgers operating in rivers, lakes, oceans and other waters.

--River dredging: Applicable to river dredging, pumping out silt, sand and gravel from the riverbed to widen the river, deepen the riverbed, improve navigation conditions or enhance flood control and drainage.

--Mining industry: Used to transport slurry and tailings generated during mining, especially for large particles and highly abrasive slurries, the KG-series gravel pumps operate stably and reliably.

--Metal smelting: Suitable for conveying slag during metal smelting. The slag, characterized by large particles, high hardness and strong abrasiveness, can be transported to designated locations for treatment.

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425