250 Centrifugal Sand Pump Parts

Kenda products and components are designed to be 100% interchangeable with industry-leading brands, ensuring seamless integration and reduced downtime.

KENDA Supreme Centrifugal Sand Pump Parts | High-Performance Centrifugal Pumps & Premium Replacement Parts

At KENDA, we provide more than just equipment—we deliver fluid handling solutions engineered for the most demanding environments. Whether you need a bare pump, a complete pump package, or expert refurbishment services, KENDA is your trusted partner for reliability and precision.

Universal Compatibility

Our products and components are designed to be 100% interchangeable with industry-leading brands, ensuring seamless integration and reduced downtime. We support equipment originally sourced from:

· NOV Mission Magnum / Halco / O’Drill MCM

· Forum Energy / Double Life / Southwest

· ABCO / Mesco / TSC / Midcontinents / Dupagro

· All major Chinese Mission-style pump manufacturers

Comprehensive Repair & Component Solutions

We offer a full suite of high-durability replacement parts and repair services, engineered to withstand the most abrasive and corrosive environments:

Component | Material & Specifications |

Casing & Impeller & Stuffing Box | High-Chrome Alloy (26%), Hard Iron, SS304, SS316 Stainless Steel |

Bearings | Genuine SKF Bearings for high-load stability |

Shaft | 40Cr Heat-Treated Steel for superior strength |

Shaft Sleeve | Ceramic-Coated or Stainless Steel shaft sleeves to minimize wear. |

Mechanical Seal | Premium Tungsten Carbide (TC) |

Seals & O-Rings | High-grade NBR, Viton, Teflon, or Graphite packing |

Housing Gaskets | Heavy-duty Fiber housing gaskets |

Typical Configurations:

3x2x13 6x5x14

4x3x13 8x6x11

5x4x14 8x6x14

6x5x11 10x8x14

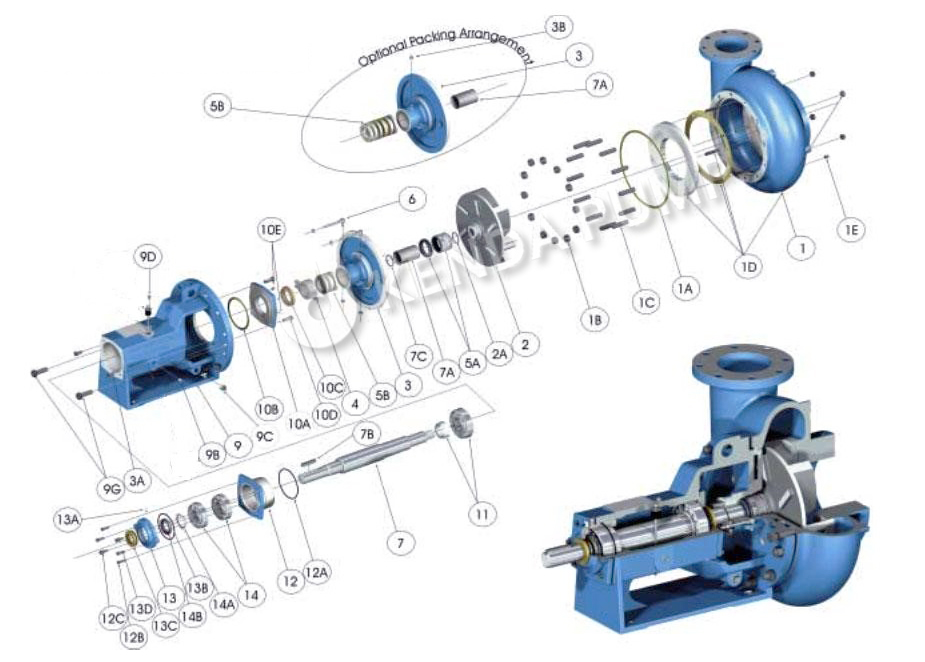

Kenda Supreme Centrifugal Sand Pump Parts List

![]()

Item | Qty | OEM Part No. | Description | Material | Weight kg |

1* | 1 | See below | Casing | ||

1A | 1 | 10399-46-1 | Gasket,casing | Vellumoid | 0.01 |

1B | 12 | 3932-61 | Nut,casing | Stl | 0.05 |

1C | 12 | H2507-3 | Stud,casing | Stl | 0.16 |

1D* | 1 | See below

| Wear pad.includes Stds,rucs&gskt | ||

1E | 1 | 8505-2H | Plug,Casing Drain | Stl | 0.03 |

2* | 1 | See below | Impeller | ||

2A | 1 | H19110-72 | Seal,impeller | Viton | 0.002 |

3*# | 1 | H22223-01-30 | Stuffing box,mech.seal | Hard Iron | 20 |

3*& | 1 | H20614-01-30 | Stuffing box,packed | Hard Iron | 20 |

3A | 2 | H3861-117 | Bolt,stuffing box | Stl | 0.05 |

3B& | 1 | 19368-1H | Grease fitting | Stl | 0.01 |

4 | 2 | H20622AH | Gland assy,packing | Stl 304 | 1 |

5A# | 1 | H22451-1A | Seal,mechanical | Tung/Tung | 1 |

5B~ | 1 | 8264-24-0B | Packing, Shaft | 0.7 | |

6 | 2 | 20629 | Bolt assy,gland | Stl 304 | 0.15 |

7 | 1 | H20612-02-33 | Shaft | 42CrMo | 17 |

7A# | 1 | H20613-21A | Sleeve,Shaft | 1 | |

7A& | 1 | H20613-21G-7A | Sleeve,Shaft(Ceramic) | 1 | |

7B | 1 | H4372-5-21 | Key,Shaft | Stl | 0.11 |

7C | 1 | 23444-01-72 | Seal,Shaft Sleeve | Viton | 0.005 |

8 | 1 | 22210-1A | Deflector,Assembly | Composite | 0.4 |

9 | 1 | H17444 | Frame,Grease Lubricated | Cast iron | 80 |

9C | 1 | Plug,Frame Drain | Stl | 0.033 | |

9D | 1 | H8267-1 | Breather | Stl | |

9G | 2 | H2538-1 | Bolt,Casing Jack | Stl | |

10A | 1 | H17950 | Cover,Inboard Bearing | Iron | 2.6 |

10B | 1 | H20625 | Gasket, Inboard Bearing Cover | Vegetable fiber | 0.01 |

10C | 1 | H2564-4 | Labyrinth Seal,IB Brg Cvr | Buna-n | 0.06 |

10D | 2 | H3861-1 | Bolt,I.B.Brg.Cover | Stl | 0.03 |

10E | 1 | Grease Fitting | Stl | ||

11 | 1 | N/A | Bearing,Inboard | Vendor | 2.1 |

12 | 1 | H20624-01-01 | Houding,O.B.Bearing | Iron | 6 |

12A | 1 | H7496-253 | Seal,O.B.Brg Housing | Buna-n | 0.01 |

12B | 4 | H3861-138 | Bolts,O.B.Brg.Housing | Stl | 0.05 |

12C | 2 | H3932-62 | Nut,O.B.Brg.Housing | Stl | 0.016 |

13 | 1 | 20617A | Cover,O.B.Bearing | Iron | 1.8 |

13A | 1 | Grease Zerk,O.B.Brg.Cvr. | Stl | 0.01 | |

13B | 1 | H7496-26 | O-ring,O.B.Bearing Cover | Buna-n | 0.001 |

13C | 1 | H2564-3 | Labyrinth Seal,O.B. Brg Cvr. | Buna-n | 0.04 |

13D | 2 | H3861-139 | Bolt,O.B.Brg.Cover | Stl | 0.025 |

14 | 2 | H20616-1S | Bearing,O.B.(2 Req’d) | Vendor | 1.5 |

14A | 1 | H6124-4 | Lockwasher,O.B.Bearing | Stl | 0.01 |

14B | 1 | H6123-4 | Locknut,O.B.Bearing | Stl | 0.22 |

Casings-includes studs,nuts & gasket | |||||

1* | 1 | H19203-01-30A | Casing,3×2×13 | Hard Iron | 55 |

1* | 1 | H19205-01-30A | Casing,4×3×13,w/ wear pad | Hard Iron | 55 |

1* | 1 | H19222-01-30A | Casing,5×4×14 w/ wear pad | Hard Iron | 85 |

1* | 1 | H19122-01-30A | Casing,6×5×11 w/ wear pad | Hard Iron | 88 |

1* | 1 | H19123-01-30A | Casing, 6×5×14 w/ wear pad | Hard Iron | 90 |

1* | 1 | H19763-01-30A | Casing, 8×6×11 w/ wear pad | Hard Iron | 95 |

1* | 1 | H19117-01-30A | Casing,8×6×14 w/ wear pad | Hard Iron | 125 |

1* | 1 | H20937-01-30A | Casing,10×8×14 w/ wear pad | Hard Iron | 150 |

Impellers and Casing Wear Pads | |||||

2* | 1 | H19204-XX-30 | Impeller,3×2×13 Open | Hard Iron | 9 |

2* | 1 | H19206-XX-30 | Impeller,4×3×13 Open | Hard Iron | 12.5 |

2* | 1 | H2523-XX-30 | Impeller,5×4×14 Semi Open | Hard Iron | 18 |

2* | 1 | H2523-XX-30 | Impeller,6×5×11 Semi Open | Hard Iron | 17 |

2* | 1 | H2523-XX-30 | Impeller, 6×5×14 Semi Open | Hard Iron | 22 |

2* | 1 | H2524-XX-30 | Impeller, 8×6×11 Semi Open | Hard Iron | 23 |

2* | 1 | H2524-XX-30 | Impeller,8×6×14 Semi Open | Hard Iron | 25 |

2* | 1 | H2526-XX-30 | Impeller,10×8×14 Semi Open | Hard Iron | 26 |

1E | 1 | H2501-01-30A | Wear Pad,4×3×13 Casing | Hard Iron | 9 |

1E | 1 | H2502-01-30A | Wear Pad,5×4×14 Casing | Hard Iron | 9.5 |

1E | 1 | H2503-01-30A | Wear Pad,6×5×11 Casing | Hard Iron | 8.5 |

1E | 1 | H2504-01-30A | Wear Pad, 6×5×14 Casing | Hard Iron | 10 |

1E | 1 | H2505-01-30A | Wear Pad, 8×6×11 Casing | Hard Iron | 9.5 |

1E | 1 | H2506-01-30A | Wear Pad,8×6×14 Casing | Hard Iron | 11 |

1E | 1 | H2507-01-30A | Wear Pad,10×8×14 Casing | Hard Iron | 12 |

Note:

1. XX-Impeller code-Firsr X equals diameter of impeller in inches minus 4.Therefore 10″=6,9″=5 etc…14″ use lettet A;

2. Second X equals frational data in1/8′s.Therefore 1/8″=1, 1/4″=2 ,etc…Thus a 10.5″impeller is coded as 64, 12″impeller is coded as 80, 13.25″impeller is coded as 92 etc…

3. YYY-the metric diameter of impeller,therefore 12″ is coede as 305mm,11″ is coded as 280mm

Application:

| Application | Industry Use Cases | Industry Focus |

|---|---|---|

| Oil & Gas Drilling | Mud mixing, desander & desilter feeding, and supercharging systems. | Drilling Mud Pump, Solid Control |

| Mining & Slurry | Tailings transport, mine de-watering, and abrasive coal slurry handling. | Slurry Transfer, Mineral Processing |

| HDD Construction | Bentonite mixing for horizontal directional drilling and tunneling. | HDD Mud System, Bentonite Pump |

| Industrial Use | Fly ash handling, waste water treatment, and lime slurries. | Abrasive Fluid Handling, Industrial Pump |

Disclaimer: All brand names and trademarks (such as NOV Mission Magnum, Halco, etc.) are the property of their respective owners. Reference to these brands is for compatibility and identification purposes only. KENDA is not an authorized distributor or representative of these manufacturers. Our products are high-quality, non-OEM replacement parts designed to be 100% interchangeable with the original equipment.

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425